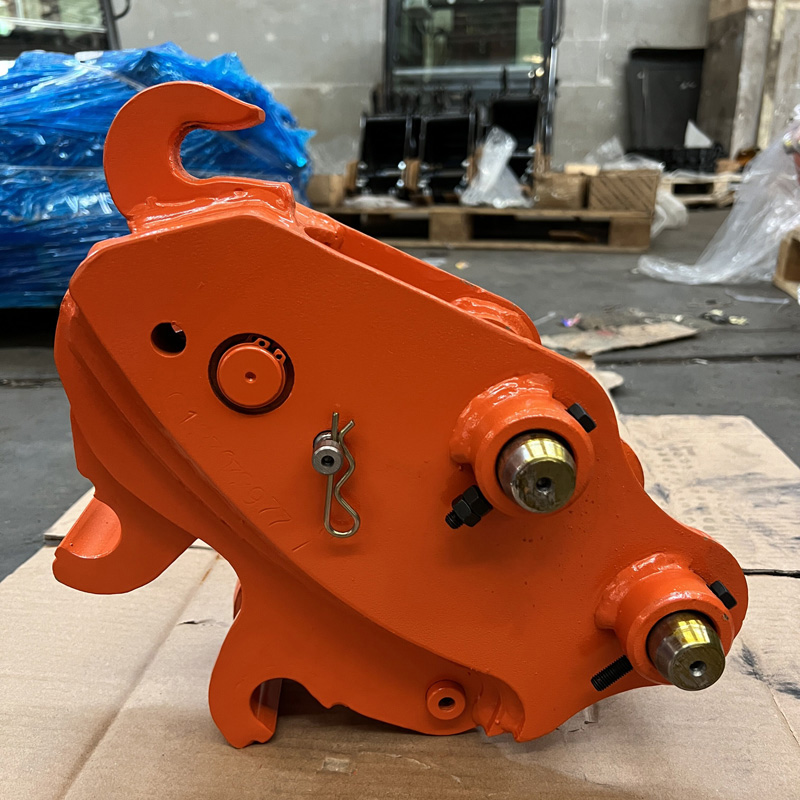

Hydraulic Quick Hich

The complete set of hydraulic systems are international well-known brands, no rust, no valve jamming, etc. regardless of wind, sun, rain, etc. At the same time, the products can be customized to meet the needs of different countries and customers. It can be applied to a variety of complex environment operations, whether it is mountains, hills, terraced fields, hard ground, paddy fields, it can be easily done.

Open gear: 110mm

Axle spacing: 105mm

Product Introduction

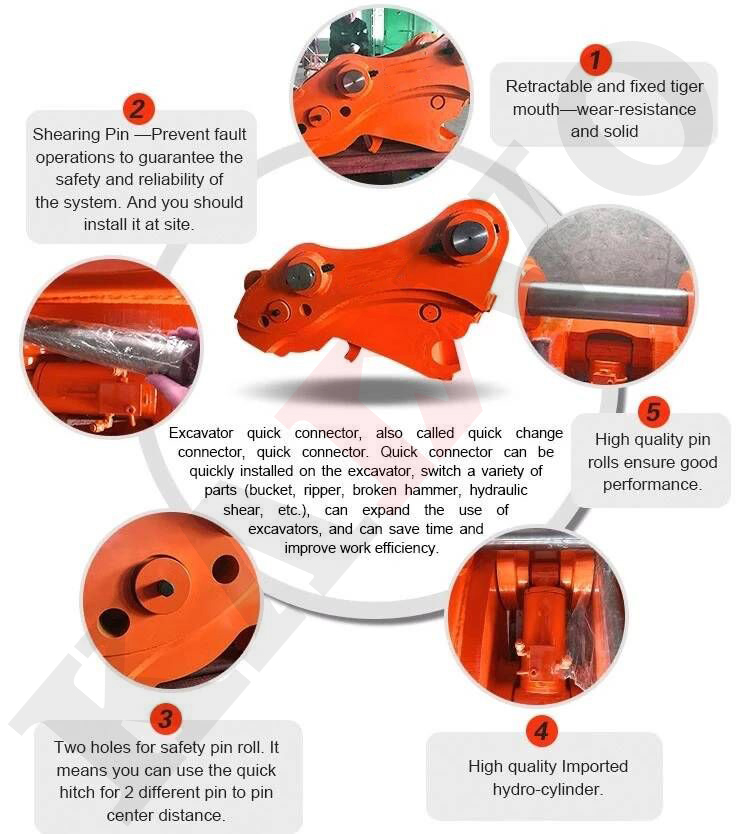

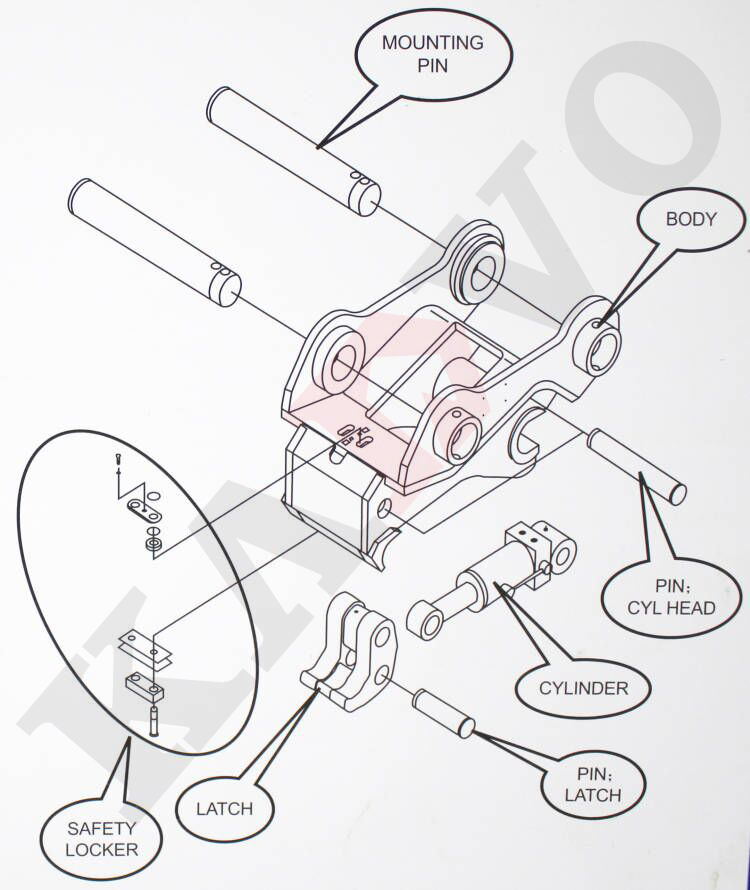

The hydraulic quick hitch joint requires modification of the excavator pipeline and hydraulic system to meet the requirements of automatic replacement of the working device (convenient, practical, and high cost), and is used to frequently switch various accessories of the excavator (digging bucket, scarifier, crushing hammer, and grabber). Hydraulic quick change can be easily replaced with various accessories, which is quite convenient and fast for excavator operators. Compared to mechanical quick change, hydraulic quick change is safer, and there is no need to twist the lead screw when getting off the car. Slowly, mechanical quick change is completely replaced.

Hydraulic Quick Hitch Features

1. Use a safety device with a hydraulic control one-way valve to ensure safety.

2. The excavator configuration components can be replaced without modification or disassembly of the pin shaft, so installation is fast and can greatly improve work efficiency.

3. There is no need to manually smash the bucket pin between the crushing hammer and the excavation bucket. Gently moving the switch for ten seconds can complete the exchange between the excavation bucket and the crushing hammer, which is time-saving, labor-saving, and simple and convenient.

4. Mainly used in workplaces that require frequent replacement of the front-end working device of excavators, it is recommended to avoid installing a device for long-term use.

Send Inquiry